High Quality Lowest Price Three in One Fiber Laser Machine Welding Cutting Cleaning 1kw 1.5kw 2kw Industrial Machinery Machine

Basic Info.

| Model NO. | ST-F |

| Technical Class | Continuous Wave Laser |

| Control | Manual |

| Power Density | Deep Fusion Welding |

| Laser Classification | Optical Fiber Laser |

| Type | Portable Welding Machine |

| Control System Brand | Hanwei |

| Laser Head Brand | Hanwei |

| Machinery Test Report | Provided |

| Core Components | Laser Source |

| Wavelength | 1064nm |

| Pulse Width | 0.05-4mm |

| Focal Spot Diameter | 0.2-3.0mm |

| Laser Source Brand | Raycus, Max, Jpt, Reci, etc |

| Power Supply | 220V/380V 50Hz/60Hz |

| Application Material | Aluminum Stainless Steel Carbon Steel |

| Laser Power | 1000W 2000W 3000W (Optional) |

| Welding Mode | Manual Handheld |

| Laser Source | Raycus Ipg Jpt Max Optional |

| Cooling System | Water Cooling System |

| Warranty of Core Components | 2 Years |

| Transport Package | Wooden Box |

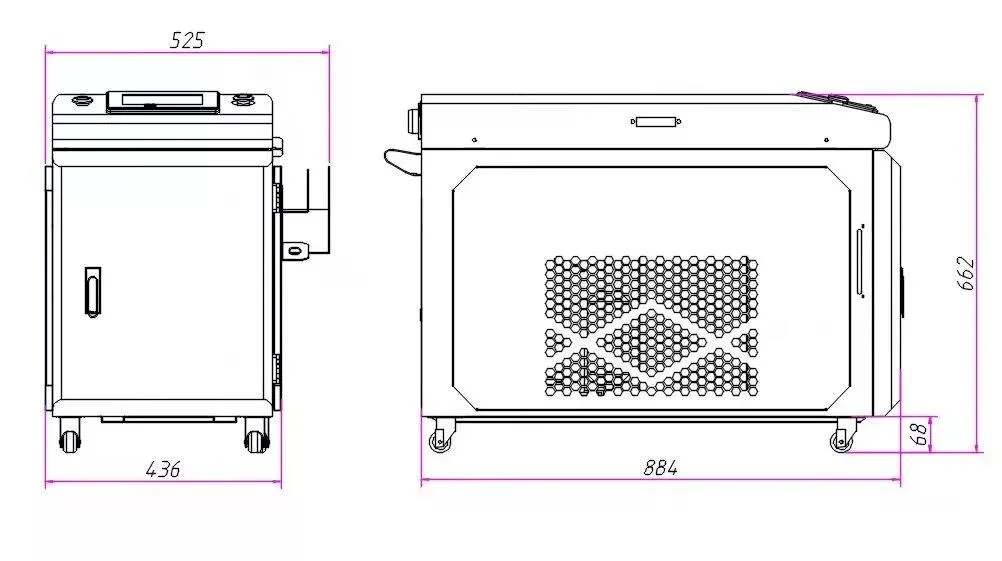

| Specification | weight: 155kg, volume(mm): 884*662*436 |

| Trademark | MORITA |

| Origin | Chine |

| HS Code | 8515809010 |

| Production Capacity | 2000sets/Year |

Packaging & Delivery

Package Size 105.00cm * 54.00cm * 92.00cm Package Gross Weight 170.000kgProduct Description

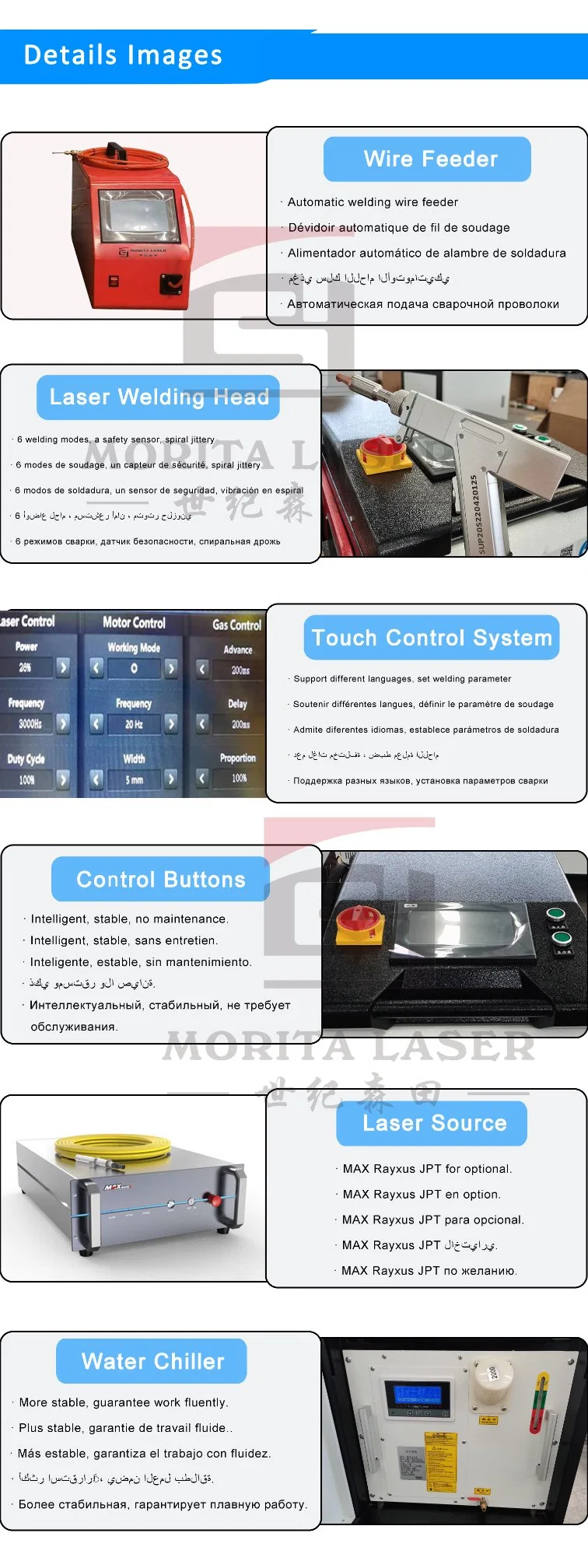

Water Cooling SystemLaser Welding TypeContinuous Laser WeldingLaser Frequency50-5000HzPower Range10-100%Fiber Length5m/10m/15m, optionalPower Supply220V/1P for 1000W and 1500W, 380V/3P for 2000W and 3000WCooling MethodWater CoolingWorking EnvironmentTemperature -10-40 ° C, Humidity < 90%Cabinet Size525*884*662mmPackaging Size1070*530*1100mmMass Weight175kgDetailed PhotosAdvantages of Handheld Laser Welding Machine with Fiber Laser Beam:1. Handheld welding head is equipped with 1000 watt fiber laser power, flexible, enabling outdoor welding.2. Fast welding speed, 2-10 times faster than traditional welding.3. The welding seam smooth and beautiful, large depth, small taper, don't need polish, save time.4. No deformation or welding scar, firm welding of the workpiece.5. Laser welding has less consumables, low energy consumption and long service life.6. Safety, easy operation and more environmentally friendly.

Handheld Laser Welding Machine Applications:

Handheld laser welding machine can be used for welding stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys, it can also be used for a variety of welding between different materials, including copper - brass, titanium - molybdenum, titanium - gold, nickel - copper, and so on.

| Type | Traditional Welding | Handheld Laser Welding |

| Situation of Welding Heat-input | very high | very low |

| Situation of Subsequent Processing | polish | no or few polish |

| Situation of Welding Speed | general | More than 2 timesas traditional welding |

| Situation of Consumptive Materials | more | less |

| Situation of Operation Difficulty | complicated | simple |

| Security for Wokers | unsafe | safe |

| Impact of Environmental protection | not environmentally friendly methods | environmentally friendly methods |

| Light Spot width Adjustable | no | yes |

| Welding Fault Tolerance | good | good |

| Welding Quality | inferior | good |

Handheld laser welder machine is widely used in the kitchen cabinets, staircase elevator, shelf, oven, stainless steel door, window guardrail, distribution box, medical equipment, communications equipment, battery manufacturing, craft gifts, household and other industries.

Fiber Laser Welding Machine

Sample DisplayPackaging & Shipping

Laser equipment is a relatively precise machine, beware of bump and friction in the process of transportation, which requires us to do a good job of packaging before transportation. Morita, as a professional manufacturer of laser equipment in China, has a lot of experience in packaging all kinds of laser equipment. 1. Wipe the machine, the machine is wiped clean, not only for beautiful, more important is to prevent the machine attached to the machine is in the process of transport of particles cut surface, damage the paint. 2. We will use stretch film to winding machine,let the machine with a layer of protective film, this is to let the machine during transport to prevent damage in the process offriction. 3. We'll let the machine then wrapped with thick foam board, this can prevent machine in the process of transportation by knock against, impact. 4. Installation of wooden boxes, thick wooden cases like a layer of armor, can protect the machine to a great extent. 5. In front of the cover in the middle of the machine and the cases filled with rubber cushion, this will prevent collision between machines and wooden case, can also further to package the machine.

From Customers

Company Profile· With 15 years experience, MORITA LASER has established a complete system for the development and manufacture of laser marking, cutting, engraving and welding technologies.· Main products: fiber laser cutting machine, fiber laser marking machine, crystal engraving machine, CO2 laser marking machine, UV laser marking machine, laser engraving machine, laser cutting machine, CNC engraving machine, CNC processing center, stone engraving machine and other products.

Our products and services are the best, we provide products to many suppliers and buyers, we attach great importance to product quality, we have 14 years of experience in manufacturing personnel to process and manufacture products, before the products are shipped, we have professional inspection personnel to test the products repeatedly, to ensure that the products are the best.

As a responsible company, we are dedicated to develop new techniques out of concern of environmental protection. Disposable products are the first priority. In the near future, we will launch more and more environmental friendly products.

Q1: Is your company a manufacturer or a trading company?A1: We are a manufacturer, founded in 2009, now in Shandong, China. Committed to providing For the majority of users to provide economic, high quality laser equipment. Welcome to our factory.Q2: How can we guarantee quality?A2: Always a pre-production sample before mass production; Always final Inspection before shipment.Q3: What can you buy from us?A3: Laser marking machine, Fiber Laser cutting machine, Laser engraving machine, Laser welding machine, 3d engraving machine Q4: How long does it take to learn the laser? A4: The software is easy to learn with teaching video, also we can help you to learn the laser online. Usually it will take a few hours to operate the laser ,But it will take a bit of trial and error to learn what speed and power settings to use with different materials. So we include a comprehensive guide with your system that has recommended speed and power settings for various materials with which you will be working. Q5: What should I do when something goes wrong with the laser? A5: We offer a two-year warranty. In warranty, we will provide the broken items free of charge. Beyond the warranty period, we still provide maintenance service. Q6: Will the laser machine be safe during transport? A6: (1) Inner: plastic stretch film and white foam.(2)Middle: small pieces of wood and screws.(3)outside: standard export wooden case. So,the laser machine will send to you safely. In case the machine was damaged , please contact us ,We will process the replacement as soon as possible to ensure that it arrives in time . Q7: How deep can it engrave into metal? A7: All metals can be engraved into with some depth; However, some metals are more amenable to depth engraving. Softer aluminum material will engrave with depth with only a few passes. The best way to test your material is with our Applications Lab.