Category

12000bph Automatic Beverage Bottle Shrink Sleeve Labeling Machine with PVC Label

Package Size 350.00cm * 100.00cm * 180.00cm Package Gross Weight 3000.000kg Product Description Technical Parameter WOUL

Basic Info.

| Model NO. | LUYE |

| Type | Sleeve Labeling Machine |

| Driven Type | Electric |

| Classification | Automatic Vertical Round Bottle Labeling Machine |

| Packaging Material | Plastic |

| Packaging | Bottles |

| Suitable Label | PVC / PE / OPS Shrink Label |

| Usage | Beverage Bottle / Can/ Cups |

| Motor | Servo Motor |

| Capacity | 100-450 Bpm |

| Transport Package | Wooden Package |

| Specification | By Model |

| Trademark | LUYE |

| Origin | Zhangjiagang |

| HS Code | 8422309090 |

| Production Capacity | 20sets/Month |

Packaging & Delivery

Package Size 350.00cm * 100.00cm * 180.00cm Package Gross Weight 3000.000kgProduct Description

Product Description

Technical Parameter

| Name: shrink sleeve labeling applicator | ||||

| Model | SPC150 | SPC250 | SPC300 | SPC450 |

| Host size | 2100*850*2000 | 2100*850*2000 | 2100*1100*2200 | 2500*1200*2200 |

| Production speed | 150B/MIN | 200B/MIN | 300B/MIN | 450B/MIN |

| Suitable label material | PVC label / PET label / OPS Shrink label | |||

| Power Supply | 2.2kw | |||

| Framework material | Stainless Steel | |||

| Length of the label | 30mm~260mm | |||

| Thickness of the label | 0.03mm~0.13mm | |||

| Diameter of bottles | 28mm~125mm | |||

| High of bottles | 50mm~280mm | |||

| shape of bottles | Square, round, oval, flat bottle | |||

| Contraction furnace power | 18KW~36KW | |||

| Application | shrink sleeve labeling applicator | |||

Main Features

1, the machine is made of stainless steel and high quality of aluminum alloy, the reasonable, intact frame, it is easy to adjust.2, the feet bolt is not fixed, easy to move suitable for different place.3, the shrinkable film roll with adjustable locking gear, can be adjusted according to different roll 5-104, the applicable bottle is the machine square bottle and round bottle5, without tools, the driven machinery can be adjusted to meet different bottle size 6, particular inserting label ways, i.e. inserting label, it is reasonable and convenient.7, full automatic feeder, the flat shrinking and tension are adjusted together.8, it is assured to low error that there is inspection of rolling label cut.9, particular blade design, blade base can be change by free, changing blade quickly and conveniently.10, it is easy to change the central clamping device without any tools.11, oriental rolling label device can be lifting synchronal.12, the separating bottle screw, oriental belt and conveyor are adjusted synchronal, it is easy and quick to do.13, stainless steel electric controller, adopting Mitsubishi PLC made in Japan14, adopting advanced machine automatic controlling technology, main component adopts famous brand.

Machine Details Description:

| Sleeve Labeling Machine Application: PVC / PET / OPS label sleeve* Stainless steel Main Machine Frame / Famous electrical components (SIEMENS Plc controller ,Inverter ,Mitsubishi Motor ) | |

| Shrink Tunnel Application : Label Shrink by Steam or Electric heating*Stainless steel full cover body *Water proof design *Easy adjustment for different bottle sizes*Even shrink with good steam pressure control | |

| ,k,,, | Steam generator Application : To provide steam for shrink tunnel *Full automatic steam pressure control *Automatic water feed system *High quality heating tube *water softner as optional |

| PVC / PET / OPS Shrink label Application:food, beverages, mineral water and daily products.PVC shrinkage: longitudinal shrinkage 1%-4%, transverse shrinkage 55%;PET shrinkage: longitudinal shrinkage 1% -3%, transverse contraction 70%; |

|

WOULD LIKE TO KNOW MORE ABOUT LUYE MACHINE EQUIPMENTS, FEEL FREE TO SEND US AN INQUIRY!

ADVANTAGE:

A) PLC and Touch screen full automatic control. Easy for operate

B) Fastly different bottle size replacement

C) Concise structure, reliable and durable, easy to maintain.

FAQ

1.ARE YOU MANUFACTURER OR TRADE COMPANY?

We are manufacturer, located in Zhangjiagang. We are Specialized in beverage machinery 30 years! Our company business is supply all kind of beverage filling machine, package machine, water treatment machine And complete line from A-Z for water, juice, carbonated drink, beer, Aluminum Can drink, all kind of bottle drink filling machine

2.WHAT'S THE ORDER PROCESS?

a. Inquiry-- Provide us all your clear requirements.

b. Quotation-- Official quotation form with all clear specifications.

c. Payment terms-- T/T 30% in advanced, balanced before shipment. We can talk about this when deal.

d. Shipping-- By sea, Detailed picture of package will be provided.

3.CAN YOU GIVE ME YOUR PRICE LIST?

Sorry, we are machine manufacturer, we have more than 100 items, and each machine have different bottle Type, weight, Voltage, Dimension, Capacity, Usage so on request. So please send me your detail request, then I will email you back the price.

4.WILL YOU HAVE SOME DISCOUNT?

a. To clients who bring repeat orders and large orders

b. Please contact us for Better Quote.

5.HOW CAN I INSTALL MY MACHINE WHEN IT ARRIVES?

We will send our engineer to go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

AFTER-SALES SERVICE

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the preparation conditions, our fast and professional aftersales service engineer team will go to your factory to install the machine, give you the operating manual, and train your employee untill they can operate the machine well.

3.We often ask feed back and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty.

5.Well-trained & experienced staff are to answer all your inquires in English and Chinese

6.24 hours for engineer response ( all services part 5days in customer hand by Intl' courier).

7.12 months guarantee and life-long technical support

8.Your business relationship with us will be confidential to any third party.

9.Good after-sale service offered, please get back to us if you got any questions.

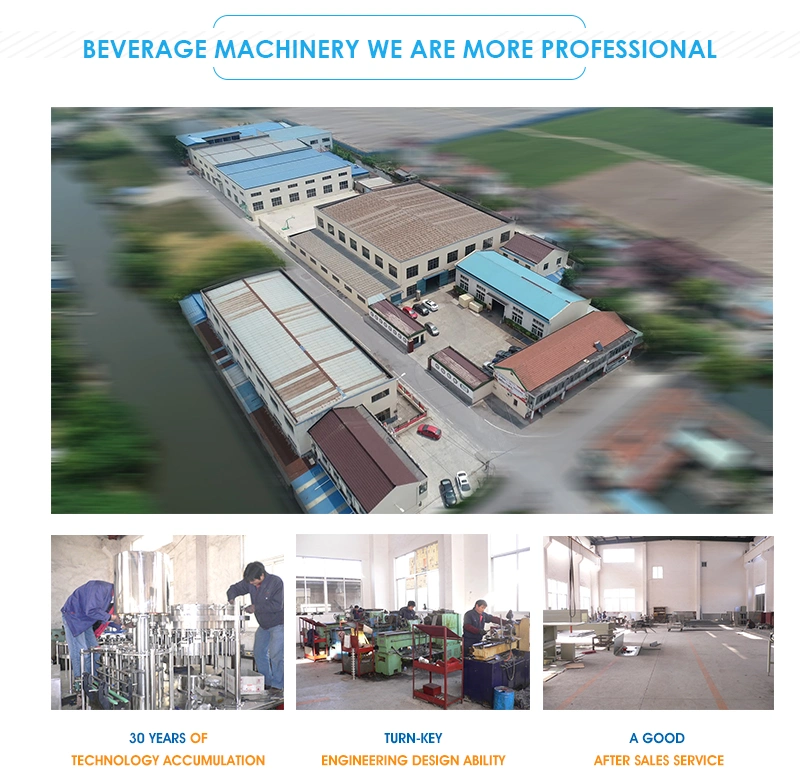

LUYE MACHINERY COMPANY INTRODUCTION:SINCE 1989

LUYE has More than 30 years Professional Manufacturer of Turn-key Beverage Machinery.

1.Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. We promise that the products of this line could storage for one year without adding any aseptic.

Certification

• Your inquiry related to our product & price will be replied within 24hours

• Well-trained & experienced staff are to answer all your inquiries in English and Chinese

• Working time: 8:30am ~6:00pm, Monday to Friday(UTC+8).

• OEM & ODM projects are both available

• Your business relationship with us will be confidential to any third party.

• Good after-sale service offered, please get back to us if you got any questions.

Welcome To Visit ZhangJiaGang LUYE Machinery CO.,LTD

Previous: Industrial Automatic Hotwater Immersion Spray Steam Retort/Autoclave/Sterilizing/Sterilization/Processing/Machine for Canned Fish Pet Food Corn Beef Sausage Egg

Next: Industry Use China Factory Supply Stainless Steel Tunnel Continuous Spray Sterilizer Cans Bottle Sterilizer and Cooler

Send inquiry

Send