Category

Tinned Canned Food Production Line Automatic Pickled Cucumber Canning Production Line

Package Size 1800.00cm * 1250.00cm * 1550.00cm Package Gross Weight 1000.000kg Cucumber Canned Production Line Technolog

Basic Info.

| Application | Vegetable |

| Customized | Customized |

| Certification | CE, ISO9001 |

| Power Source | Electric |

| Automatic Grade | Automatic |

| Key Machines | Pasteurizer, Fryer, Mixer, Heat Exchanger, Fruit&V |

| Dimension(L*W*H) | 5000*1000*2500 |

| Weight | 5000 Kg |

| Machinery Capacity | OEM |

| Transport Package | Wooden Cases |

| Specification | OEM |

| Trademark | Genyond |

| Origin | China Mainland |

| Production Capacity | Customized |

Packaging & Delivery

Package Size 1800.00cm * 1250.00cm * 1550.00cm Package Gross Weight 1000.000kgProduct Description

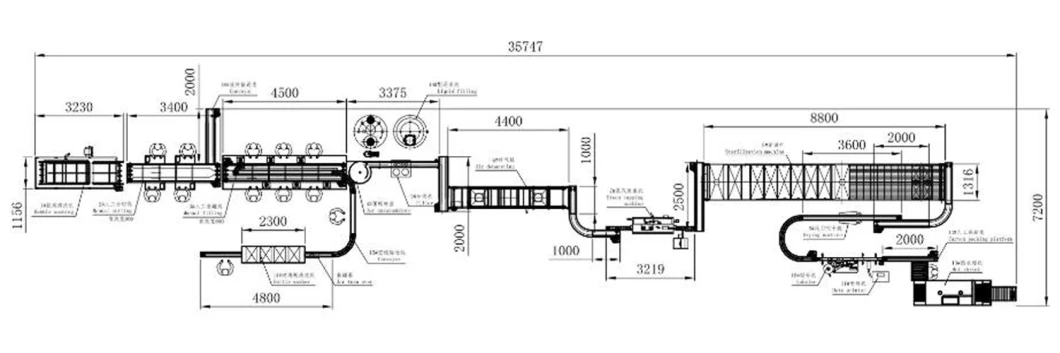

Cucumber Canned Production Line Technological Process:

Cucumber selection→lifting →cleaning→(empty bottle unloading - empty bottle cleaning and drying)→ solid filling → soup filling machine →exhaust - sealing → sterilization and cooling → labeling →code spraying→ packing→ stacking

New automatic Pickle Canned Cucumber Production Line, processing cucumbers; Bottle Washer, Vegetable Washing Machine, Filling Machine, Conveyor Elevator, Conveyor Line,Capping Machine,Pasteurizer, Empty Can De-palletizer,Pre-cooking Machine,Filled Can Palletizer,Bottle Labeling Machine.

The same line can be used for assorted vegetables, mixed salads, olives, pickled onions, sliced peppers, mushrooms.

Suitable for all jars and cans size .

| Name | Technical parameter |

| Z type elevator | Equipment material: food grade stainless steelMaterial lifting |

| Shaker | Vibration and impurity removal before soaking and cleaning of raw materials |

| Cucumber soaking washing machine | Equipment material: food grade stainless steelEquipment size: 1500*6000mmSoak, Bubble, Lift |

| Manual selecting platform | Manual selecting |

| Continuous pre-cooker | Equipment material: food grade stainless steelEquipment size: 1500*8000mmCucumbers are greened, temperature controlled |

| Continuous cooler | Equipment material: food grade stainless steelEquipment size: 1500*5000mmRapid cooling after pre-cooking to maintain product appearance |

| Z type elevator | Equipment material: food grade stainless steelMaterial lifting |

| Vibration filling machine | Filling range: 330-900g/bottleFilling speed: 80-120 bottles/min (the capacity of the machine will vary according to the size of the cucumber and the size of thebottle)Manual feeding is required after fillingEquipment material: food grade stainless steelFeed height: 1760mm |

| Automatic soup adding machine | Equipment material: food grade stainless steelsoup added |

| Capping machine | Cap, screw cap, 5000-6000 bottles/hourPower: 2.04kwSteam demand: more than 180kg/hDimensions: 3450*1040*2150mm |

| Bottles washing machine | Dimensions: 4200*1500*1800Power: 5.35kwCapacity: 120 bottles/minApplicable bottle diameter: 40-180mmSuitable bottle height: 60-300mmRinse method: two-stage cleaning (unlimited bottle type |

| Pasteurizer | Fully automatic controlEquipment material: 304 stainless steel for the whole machineAutomatic temperature control systemEquipment size: effective width 2000mm/length 25000mmInsulation on three sides |

| Air knife blowing water | Used to blow-dry the water on the surface of the jar |

| Bottles palletizer | Standard machine (universal)Tray size: 1m*1.2mJar shape: Universal glass bottleProduction speed: 1-1.5 layers/minuteEquipment size: length 6600mm width: 2300mmEquipment power: 7.5kwAir source consumption: 0.6MPa |

ASHLEY